Collab Yakima Chief Hops

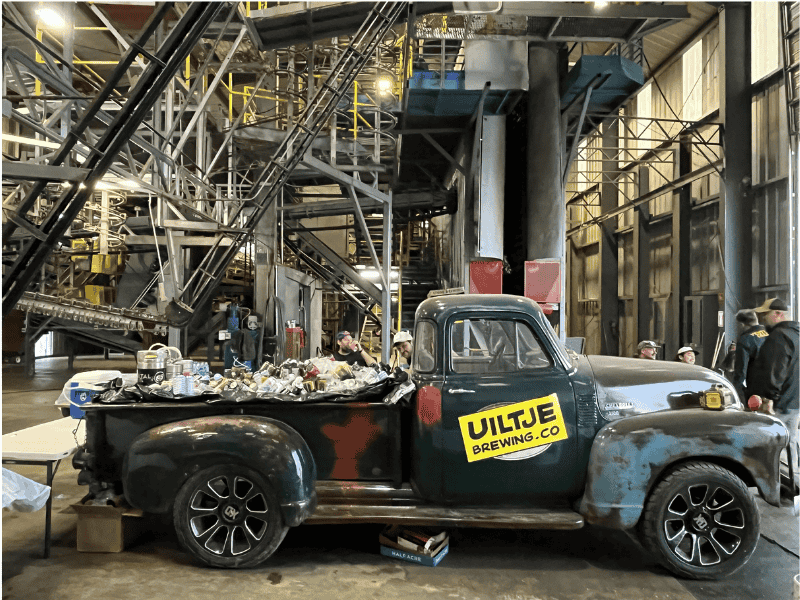

UILTJE & YAKIMA CHIEF hops

TIFFANY PITRA, SENIOR MANAGER HOP RESEARCH, YAKIMA CHIEF HOPS

On Hop Sensory, A.I. and Trying to Bottle ‘Dank’

One thing we Uiltjes have learned over the years is that hop sensory analysts and researchers are usually the most interesting people in the room. They are as heavily tattooed as brewers, but bring a cool Weird Science vibe to the table. They are almost always opinionated, wear funky socks and tend to answer with verve any questions we throw their way. A little bit emo and nerdy, exactly how we like them.

Like every other brewer on the planet, we source a sh*tload of hops from Yakima Chief Hops (YCH). Some of them, like the Krush used in our recently released Yeti Krush, are enjoying ‘a moment’. But no matter what the hop lot, every batch must pass a rigorous sensory assessment before being shipped out. During our recent trip to Yakima, we stopped by YCH’s sensory lab to ask Tiffany Pitra, Senior Manager of Hop Research, about how she scores her hops. Anyone vaguely interested in craft beer should probably read what she has to say.

UILTJE: We come with many questions, are you ready?

TP: When you put it like that, I’m not sure.

UILTJE: Sensory assessments and hop scoring is probably the most important aspect of craft brewing that no one knows anything about.

TP: Agreed. It influences everything from purchasing decisions to product use — extract, pellets and selection table.

UILTJE: Sensory assessments are part people, part science and even part A.I. Let’s start with A.I.

TP: We use A.I. to streamline and standardize our sensory scoring, especially during the busy harvest season.

UILTJE: How do you use A.I., specifically?

TP: We take photos and upload them to our A.I. model for visual assessment. It quickly spots things like cone color, mildew, uniformity.

UILTJE: How did you do things before A.I.?

TP: Two or three of us would score the hops independently, write our scores on clipboards, average the scores and then upload them. Now one person takes a photo and the A.I. model scores it. If it's within one point of the human assessment average, we accept it.

UILTJE: What are the advantages of A.I. – time saving?

TP: Speed is the most important, but A.I. also eliminates human bias and fatigue and delivers more consistency across the board.

UILTJE: Now the people side – how do you standardize the scoring?

TP: First, we use panel booths with red lighting and double-door pass-throughs (both standard controlled environment practices to guarantee testing integrity). During harvest, we are more lenient. Our panelists can assess samples anywhere, as long as they avoid distractions like food.

UILTJE: Let’s explain the process a bit? You receive a box of samples from farm X…

TP: Exactly.

UILTJE: What if the hops arrive damaged?

TP: We start by examining for obvious pest and disease damage. Severe aphid damage could result in rejection.

UILTJE: Then you sort them and present them to the panelists. Who are the panelists?

TP: We use production, sales and other internal staff, which can be tough for scheduling.

UILTJE: How do you incentivize their participation?

TP: It is written into employee goals, with financial incentives.

UILTJE: Do you have to train them?

TP: Yes. It’s a big part of what we do. We start with a long training workshop at the beginning of the year and host pop-up trainings over time.

UILTJE: Do you find that brewers are better at assessing hops than ‘normal’ people?

TP: We have found that trained panelists who participate in both hop and beer sensory tend to be strong performers. The added skillset of beer sensory knowledge is very helpful, so a brewer who has this background may be able to pick it up quickly. But we believe everyone, even without that experience or background, is trainable and has potential. It just takes proper education and consistent practice.

UILTJE: How many hop samples do panelists assess daily?

TP: During harvest, up to 48, with an hour break between each set of 12.

UILTJE: How do you keep panelists from drifting in their assessments?

TP: We monitor them closely and use training moments to correct autopilot behavior.

UILTJE: Do the panelists have to hand rub all their own hops?

TP: We grind the hops for them, which is standardized for higher throughput. Panelists

prefer that to 48 hand rubs a day.

UILTJE: Do you use panelists year-round or just during the harvest?

TP: Year-round. In Yakima, we focus on leaf sensory and at our location in Sunnyside pellet sensory. We switch to pellet sensory after receiving the bales and continue assessing through January, then we transition to research and product development projects.

UILTJE: Now the science part of assessing. Can you trace off-flavors to specific causes?

TP: Yes. Burnt rubber, onion, garlic can come from late harvest. Musty notes from under-dried hops. Cheesy and dried fruit from oxidation.

UILTJE: What varieties are most sensitive to timing?

TP: Mosaic is unpredictable and complex. Citra seems more stable. Amarillo is difficult as well. It has a long harvest window and we tend to get more off notes in leaf form than pellet.

UILTJE: Who decides harvest timing?

TP: For proprietary brands, Yakima Chief Ranches (YCR) sets harvest windows and specs. Growers can adjust based on field conditions.

UILTJE: So now the big question, the ‘real’ reason we wanted to speak with you today. Looking around, we are standing in a sensory lab with a table full of Diesel-scented candles, burnt rubber, plastic/waxy scents, herbal and spiced extracts, sweet aromatics, onion/garlic concoctions, etc. Basically, the whole sensory chart is here in physical form. So where does ‘dank’ fit into all this. We’ve been discussing this in Haarlem for years, maybe you can help us out.

TP [laughing]: Dank is hard to define. We tried training people with cannabis strains, but it didn’t help. We are now working on a dankness predictor using internal and external data.

UILTJE: Dank is used so often by brewers, yet it’s the hardest descriptor to define.

TP: You can’t put dank in a jar. It lacks a clear reference object.

UILTJE: Can you chemically analyze dankness?

TP: We compared terpene profiles of hops and cannabis. They overlap, but levels differ too much to use one marker.

UILTJE: Why do we even use the word dank then?

TP: It became popular with West Coast IPAs and is now a buzzword. I’m afraid we’ll have to live with it for now.

Helaas, nog even geen toegang voor jou.

We zien je graag weer terug als je 18 bent!

Ben je 18 jaar of ouder?

Niks persoonlijks, je moet gewoon 18 jaar of ouder zijn om onze site te bezoeken. Het is de wet, sorry!